In the fields of chemicals, coatings, and new energy materials, mixing high-viscosity substances is always a major challenge. Materials such as PE wax, car paint, adhesives, sealants, and electronic pastes require precise homogenization and efficient dispersion. Conventional mixing equipment often struggles with high energy consumption, uneven mixing, or excessive wear when processing such materials.

The LRMIX Butterfly Mixer is specifically engineered to overcome these difficulties. Its advanced configuration includes:

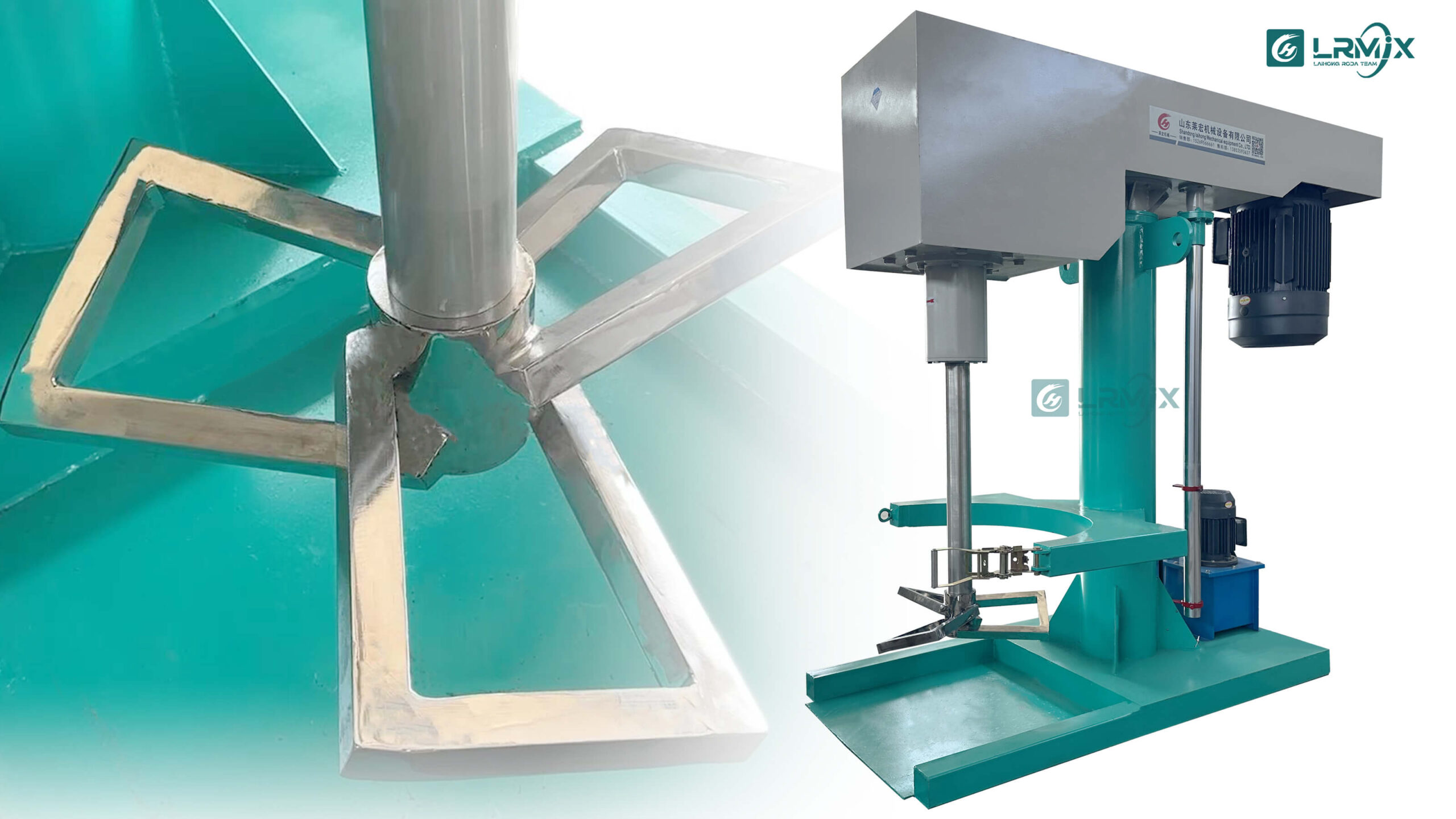

Triple-Paddle Butterfly Agitator: Creates strong material flow, eliminates dead zones, and achieves uniform mixing within a shorter cycle.

Two-Stage Motor Drive: Provides stable, efficient power output while maintaining low heat generation during continuous operation.

R-Series Helical Gear Reducer: Delivers high torque and efficient transmission, with excellent durability for long-term industrial use.

Industrial Applications of the LRMIX Butterfly Mixer:

PE Wax Blending: Ensures consistent dispersion in plastic processing and masterbatch preparation.

Car Paint & Coatings: Achieves smooth dispersion and stable rheology, improving adhesion and gloss in final products.

Electronic Pastes & Sealants: Provides high homogeneity to meet stringent standards in electronics and new energy industries.

Compared with traditional mixers, the LRMIX Butterfly Mixer offers:

Improved Mixing Efficiency – Reducing production cycles by 20–30% on average.

Consistent Product Quality – Eliminating batch-to-batch variations caused by poor dispersion.

Lower Maintenance Costs – With a compact design, easy cleaning, and long-lasting components.

Key Features:

- Mixer Type: Features a triple-blade butterfly agitator, designed with an optimized three-dimensional mixing trajectory to achieve uniform dispersion and efficient blending of high-viscosity materials. An optional PTFE wall scraper prevents material adhesion to the vessel walls, minimizing waste and enhancing mixing quality, particularly for highly viscous substances.

- Control System: Equipped with an advanced PLC intelligent control panel, offering precise parameter adjustments and real-time monitoring for seamless operation. Optional manual control buttons provide flexibility, accommodating various production scenarios and operator preferences.

- Motor and Reducer: Powered by an R-series hardened gear reducer, delivering high transmission efficiency, exceptional wear resistance, and smooth performance under heavy loads. Paired with a dual-stage motor, it provides robust torque, ensuring reliable startup for high-viscosity materials like resins or adhesives without the risk of overcurrent.

- Discharge Options: Offers bottom-side discharge or press discharge configurations, tailored to diverse production workflows. Bottom-side discharge enables rapid unloading, while the press discharge option suits processes requiring higher precision, enhancing operational efficiency.

For manufacturers dealing with high-viscosity material processing, the LRMIX Butterfly Mixer is the ultimate solution to enhance both productivity and product quality.

FAQ

Q1: Can the LRMIX Butterfly Mixer handle PE wax and car paint?

A: Yes. The LRMIX Butterfly Mixer is designed for high-viscosity materials like PE wax and car paint, ensuring uniform mixing and superior dispersion.

Q2: How often should I clean the Butterfly Mixer?

A: For sticky materials such as PE wax and coatings, daily cleaning is recommended. For less viscous pastes, cleaning every few days is sufficient. Regular maintenance extends service life.

Q3: Is the LRMIX Butterfly Mixer easy to maintain?

A: Yes. With a two-stage motor and R-series gear reducer, the machine is durable and easy to maintain. Its accessible design allows quick inspection and replacement of parts, while routine lubrication and cleaning keep operation costs low.